The Importance of Safety Shoes for Civil Engineers

When it comes to ensuring safety in the workplace, especially in high-risk environments like construction sites, safety shoes are essential. Civil engineers, who are often exposed to hazardous conditions, must prioritize wearing the right protective gear, including safety shoes. This blog explores the importance of safety shoes for civil engineers and the role of safety shoes manufacturers in providing high-quality, durable footwear that meets the needs of both civil engineers and factory workers.

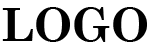

Why Safety Shoes Are Crucial for Civil Engineers

Civil engineers frequently work on construction sites where they are exposed to various dangers such as falling objects, sharp debris, and uneven surfaces. Safety shoes designed for these conditions can prevent serious injuries by providing:

- Foot Protection: Safety shoes with reinforced toe caps protect against heavy objects that may fall or roll onto the feet. This feature is crucial for civil engineers who often work in environments where the risk of such accidents is high.

- Slip Resistance: Construction sites can be slippery due to wet surfaces, oil spills, or loose gravel. Safety shoes with slip-resistant soles provide the necessary grip to prevent slips, trips, and falls.

- Electrical Hazard Protection: Many civil engineers work around electrical wiring and machinery. Safety shoes with electrical hazard protection can prevent electric shocks, a critical feature when working in such environments.

- Puncture Resistance: Construction sites are often littered with sharp objects like nails, metal shards, and glass. Safety shoes with puncture-resistant soles protect against injuries from stepping on these hazards.

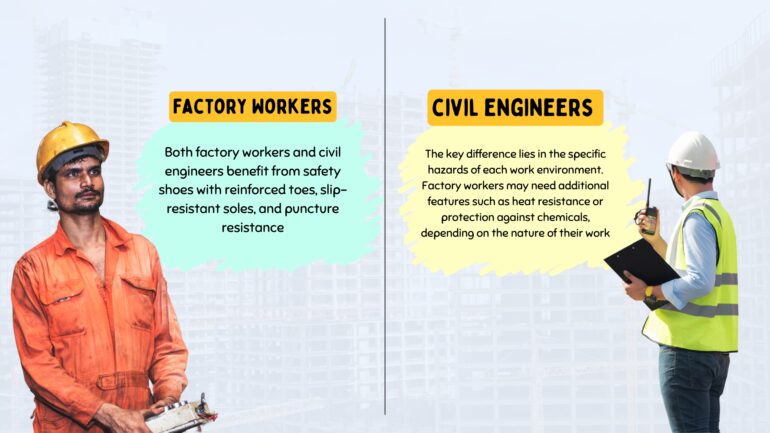

Safety Shoes for Factory Workers: Similarities and Differences

Factory workers, like civil engineers, also require high-quality safety shoes to protect against various workplace hazards. While the specific risks may differ, the fundamental need for protection remains the same.

- Similarities: Both factory workers and civil engineers benefit from safety shoes with reinforced toes, slip-resistant soles, and puncture resistance. These features are essential for preventing injuries in environments where heavy machinery, sharp objects, and slippery surfaces are common.

- Differences: The key difference lies in the specific hazards of each work environment. Factory workers may need additional features such as heat resistance or protection against chemicals, depending on the nature of their work. Civil engineers, on the other hand, may require more robust footwear that can withstand rough outdoor conditions, such as water-resistant materials and enhanced ankle support.

The Role of Safety Shoes Manufacturers

Safety shoes manufacturers play a vital role in ensuring that civil engineers and factory workers have access to high-quality protective footwear. These manufacturers are responsible for designing and producing safety shoes that meet industry standards and provide adequate protection against workplace hazards.

- Innovation and Technology: Leading safety shoes manufacturers invest in research and development to create innovative products that offer enhanced protection and comfort. For instance, advancements in materials technology have led to the production of lighter, more durable safety shoes that do not compromise on protection.

- Customization: Some manufacturers offer customization options to meet the specific needs of different industries. For example, they may produce safety shoes with specialized features like extra ankle support for civil engineers or chemical- resistant soles for factory workers.

- Compliance with Safety Standards: Reputable manufacturers ensure that their products comply with international safety standards, such as ASTM or EN ISO, which guarantee that the safety shoes provide the necessary level of protection.

Conclusion

Safety shoes are an indispensable part of a civil engineer’s protective gear, offering essential protection against the numerous hazards present on construction sites. Similarly, factory workers rely on safety shoes to protect their feet in hazardous work environments. By choosing safety shoes from reputable manufacturers, both civil engineers and factory workers can ensure they are adequately protected, reducing the risk of workplace injuries and enhancing overall safety.

When selecting safety shoes, it’s crucial to consider the specific hazards of your work environment and choose a pair that offers the right level of protection. With the right safety shoes, you can step confidently into your workday, knowing your feet are well-protected.

Read More: